Solidworks Mold Tools

You combine the design parts and mold base in the interim assembly. Then, you create a cavity feature in the context of the interim assembly. This relates the mold. This course will teach you how to design and build prototype molds for silicone parts using SOLIDWORKS Mold Tools and 3D printing. Software required: SOLIDWORKS. S Winning Eleven 2010.

CSWPA-Mold Tools. The completion of the Certified SOLIDWORKS Professional Advanced Mold Tools (CSWPA-MT) exam shows that you have successfully demonstrated your. Here is a simple Tutorial on using the Mold Tools in SolidWorks. For this tutorial we will make a simple basket and the corresponding mold. I used SoldiWorks 2012 and.

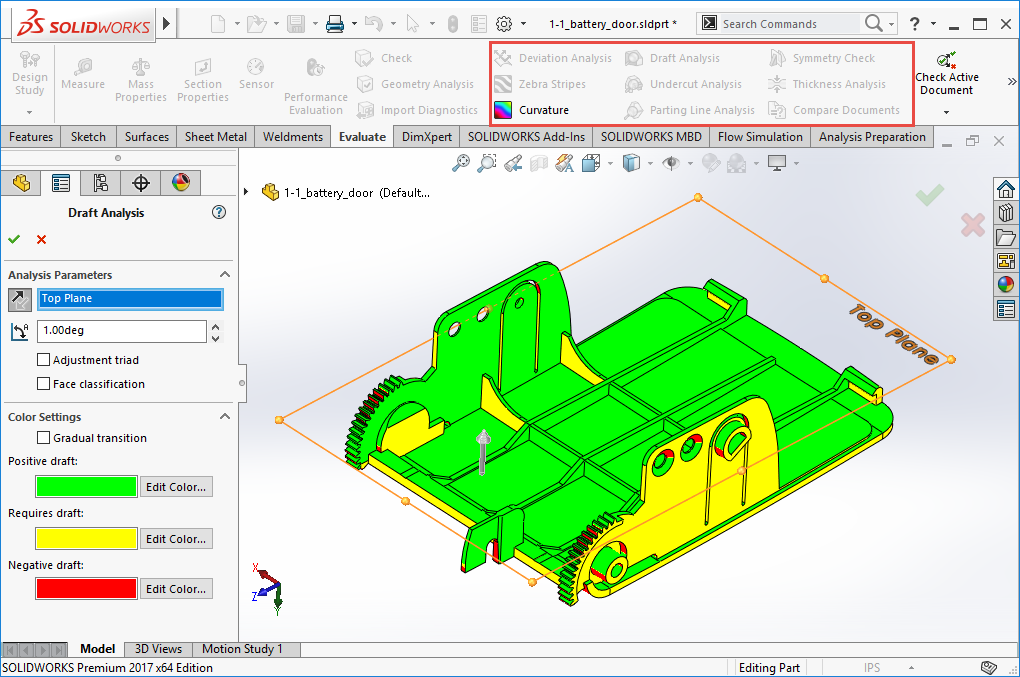

Procedural Procedural tools create the mold and tools that enable you to display the model along different stages. Diagnostic Diagnostic tools show problem areas on the model. As you create the mold, you can examine the model for potential problems that might prevent the core and cavity from separating.

Corrective Corrective tools repair the flaws, such as surface gaps, discovered by the diagnostic tools Administrative Administrative tools manage the models, facilitating the flow of information between designers, engineers, manufacturers, and managers. The model geometry in imported parts can include imperfections such as gaps between surfaces. The SOLIDWORKS application includes an import diagnostic tool to address these issues. Determine if a model (imported or built in SOLIDWORKS) includes faces without draft.

Use the Draft Analysis tool to examine the faces to ensure sufficient draft. Additional functionality includes: Face classification Display color-coded count of faces with positive draft, faces with negative draft, faces with insufficient draft, and straddle faces. Gradual transition Display the draft angle as it changes within each face. Check for undercut areas. Use the Undercut Analysis tool to locate trapped areas in a model that prevent ejection from the mold.